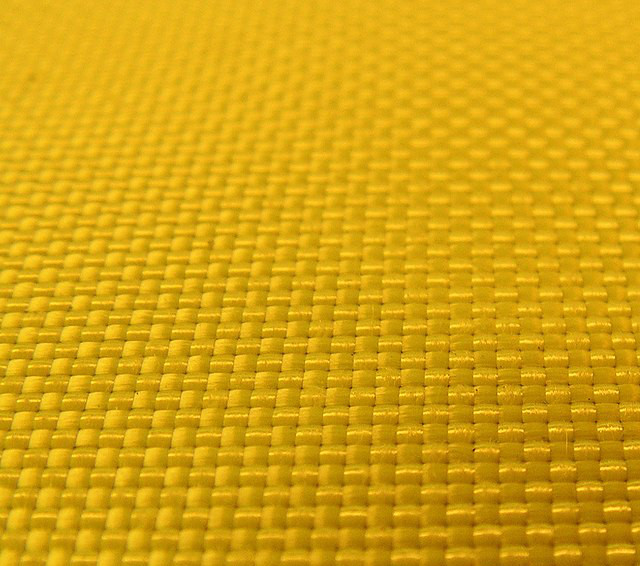

Kevlar fabrics for reinforcements for technical motorcycle garments

Technofabric: Custom production of Kevlar fabrics

Kevlar is a synthetic aramid fiber that is heat and tensile resistant, invented in 1965 by Stephanie Kwolek, a researcher at DuPont. Kevlar is used for various purposes, including personal protection, automotive, sports equipment and other uses. Kevlar has 10 times the tensile strength of steel for the same weight and can withstand temperatures up to 800 degrees Fahrenheit. Kevlar is also resistant to bullets, cuts and punctures due to its compact and aligned molecular structure.

Kevlar can be woven in a variety of ways and shapes, resulting in lightweight, flexible fabrics that can be used for the production of clothing, accessories, and devices related to individual or industrial safety and protection. For example, Kevlar fabrics is used to make bulletproof vests, cut-resistant suits and gloves, reinforcements for motorcyclists' technical clothing, helmets and hard-hats.

The main characteristics of kevlar fabrics for industrial production of technical motorcycle garments are:

High resistance to heat, fire, impact, and abrasion. Kevlar can withstand temperatures up to 800 degrees Fahrenheit1 and has a tensile strength 10 times higher than steel. It can also protect against bullets, cuts, and punctures.

Light weight and flexibility. Kevlar is about 5 times lighter than steel at the same weight and can be woven into various fabrics and shapes. It can also absorb vibrations and reduce noise.

Low thermal expansion and good electrical insulation. Kevlar has a negative coefficient of thermal expansion, which means it shrinks when heated. It also has good properties as an electrical insulator.

Resistance to solvents and chemicals, except strong acids and bases. Kevlar can resist most organic solvents and chemicals, but it can be degraded by strong acids and bases

Poor resistance to UV rays and repeated bending. Kevlar can lose its strength and color when exposed to sunlight or artificial UV sources2. It can also break down when subjected to repeated bending or folding.

These characteristics make kevlar a suitable material for making protective and reinforced clothing for motorcycle riders, such as jackets, pants, gloves, boots, and helmets. Kevlar can provide safety, comfort, and durability for motorcyclists in various conditions.

Kevlar fabric is used in technical garments for motorcyclists to provide protection in the event of a fall or impact. Kevlar is mainly found in:

Motorcycle jeans: these are denim pants reinforced with Kevlar inserts in areas most prone to abrasion, such as the knees, hips and butt. Some motorcycle jeans also have removable protectors to increase safety. Motorcycle jeans are ideal for those seeking a casual, urban style without sacrificing comfort and protection.

Motorcycle jackets: these are fabric jackets with Kevlar reinforcements in the most critical areas, such as the shoulders, elbows and back. Some motorcycle jackets also have internal or external protectors to absorb impacts. Kevlar motorcycle jackets are suitable for those looking for a versatile and breathable solution that can adapt to different seasons and weather conditions.

Motorcycle gloves: these are fabric or leather gloves with Kevlar inserts in the most stressed areas, such as the knuckles, fingers and palm. Some motorcycle gloves also have hard or soft guards to protect the hands. Kevlar motorcycle gloves are suitable for those looking for good riding feel and increased wear resistance.

Since 1978 TECHNOFABRIC Produces Technical Fabrics For Industrial Use

What We Make

Development, production and finishing of technical fabrics intended to satisfy multiple needs in a vast range of industrial applications. The factories in Costigliole Saluzzo (Weaving, R&D and services) and Piasco (specific finishing and surface treatments) are equipped with the most modern equipment and control systems to ensure that we meet and exceed customer expectations.

The fabrics of our company

- ▶ COTTON FABRICS

- ▶ POLYESTER FABRIC

- ▶ ARAMID FIBERS

- ▶ NYLON FABRICS

- ▶ NOMEX FABRICS

- ▶ KEVLAR FABRICS

- ▶ POLYPROPYLENE FABRICS

ITA

ITA  DE

DE